- The screws will generally conforms to IS : 2269, ISO 10642 and DIN 7991.

- Threads will confirm to class 4g6g of IS : 4218, Coarse Series.

- Material : Mita High Grade Alloy Steel.

- Heat Treatment : HRC 38 – 44.

- Propety Class : 12.9.

- Sizes in brackets are non-preferred standards.

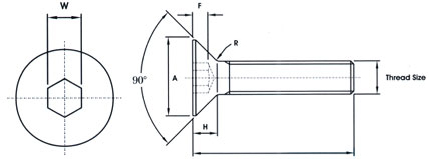

- All dimensions are in millimeters.

|

Physical Properties

| Ultimate Tensile Strength, Min. | 1,050 N/mm2 | 107 kgf/mm2 |

| Yield strength, 0.2% offset, Min. | 945 N/mm2 | 96.3 kgf/mm2 |

| Shear strength, Min. | 630 N/mm2 | 64.2 kgf/mm2 |

| Elongation % on GL = 5.65 Where A = Cross sectional area |

9% mm2 | 9% Min. |

Socket Countersunk Head Screws Inch Series – Dimensions

| Thread Size | T.P.I. | A Max | F Min. | H Min. | R Ref. | W Nom. | L Max. | |

| BSW | BSF | |||||||

| 3/16 | 24 | 32 | 0.356 | 0.065 | 0.085 | 0.025 | 3/32 | 1 |

| 1/4 | 20 | 26 | 0.475 | 0.085 | 0.113 | 0.025 | 5/32 | 1 1/4 |

| 5/16 | 18 | 22 | 0.594 | 0.105 | 0.142 | 0.025 | 3/16 | 1 1/4 |

Physical Properties

| Ultimate Tensile Strength, Min. | 1,60,000 lbf/in2 |

| Yield strength, 0.2% offset, Min. | 1,44,000 lbf/in2 |

| Shear strength, Min. | 96,000 lbf/in2 |

| Elongation % on GL = 5.65 Where A = Cross sectional area |

9% Min. |