- The bolts and screws will generally conforms to IS : 1364, ISO 4071 and DIN 931/933.

- Threads will confirm to class 6g of IS : 4218, Coarse Series.

- Material : Mita High Grade Carbon/Alloy Steel.

- Heat Treatment : Propety Class : 10.9 or 8.8 of IS : 1367.

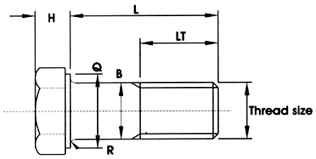

- Thread Length LT

a. Lt1 for L < 125

b. Lt2 for L < 125 to 200

c. Lt3 for L > 200 - Screw Lengths equal to or shorter than those listed in row ‘LFT’ will be threaded to head.

- Sizes in brackets are non-preferred standards.

- All dimensions are in millimeters.

| Thread Size |

Pitch | W Max | C Min. | B Max. |

H Nom. |

R Min. |

Q Min. | Length of Thread | Length Range L | |||||

| Lt1 | Lt2. | Lt3. | LFT | |||||||||||

| M4 | 0.7 | 7.0 | 7.66 | 4.0 | 2.8 | 0.2 | 5.9 | 14 | — | — | 20 | 10-40 | ||

| M5 | 0.8 | 8.0 | 8.79 | 5.0 | 3.5 | 0.2 | 6.9 | 16 | — | — | 20 | 10-50 | ||

| M6 | 1.0 | 10.0 | 11.05 | 6.0 | 4.0 | 0.25 | 8.9 | 18 | — | — | 25 | 10-50 | ||

| M8 | 1.25 | 13.0 | 14.38 | 8.0 | 5.3 | 0.4 | 11.6 | 22 | 28 | — | 30 | 12-90 | ||

| M10 | 1.5 | 17.016.0 | 18.90 | 17.80 | 10.0 | 6.4 | 0.4 | 15.6 | 26 | 32 | 45 | 35 | 16-90 | |

| M12 | 1.75 | 19.0 | 18.0 | 21.10 | 20.3 | 12.0 | 7.5 | 0.6 | 17.4 | 30 | 36 | 49 | 40 | 20-280 |

| (M14) | 2.0 | 22.0 | 21.0 | 24.49 | 23.45 | 14.0 | 8.8 | 0.6 | 20.5 | 34 | 40 | 53 | 45 | 25-200 |

| M16 | 2.0 | 24.0 | 26.75 | 16.0 | 10.0 | 0.6 | 22.5 | 38 | 44 | 57 | 50 | 25-280 | ||

| (M18) | 2.5 | 27.0 | 30.14 | 18.0 | 11.5 | 0.6 | 25.3 | 42 | 48 | 61 | 60 | 40-200 | ||

| M20 | 2.5 | 30.0 | 33.53 | 20.0 | 12.5 | 0.8 | 28.2 | 46 | 52 | 65 | 60 | 40-280 | ||

| (M22) | 2.5 | 32.0 | 34.0 | 35.72 | 37.72 | 22.0 | 14.0 | 0.8 | 30.0 | 50 | 56 | 69 | 65 | 50-280 |

| M24 | 3.0 | 36.0 | 39.98 | 24.0 | 15.0 | 0.8 | 33.6 | 54 | 60 | 73 | 75 | 50-280 | ||

| (M27) | 3.0 | 41.0 | 45.20 | 27.0 | 17.0 | 1.0 | 38.0 | 60 | 66 | 79 | 85 | 70-300 | ||

| M30 | 3.5 | 46.0 | 50.85 | 30.0 | 18.7 | 1.0 | 42.7 | 66 | 72 | 85 | 85 | 75-300 | ||

| (M33) | 3.5 | 50.0 | 55.55 | 33.0 | 21.0 | 1.0 | 46.6 | 72 | 78 | 91 | 95 | 75-300 | ||

| M36 | 4.0 | 55.0 | 60.79 | 36.0 | 22.5 | 1.0 | 51.1 | 78 | 84 | 97 | 100 | 80-300 | ||

| (M39) | 4.0 | 60.0 | 66.44 | 39.0 | 25.0 | 1.0 | 55.9 | 84 | 90 | 107 | 110 | 90-300 | ||

| M42 | 4.5 | 65.0 | 72.02 | 42.0 | 26.0 | 1.2 | 61.6 | 90 | 96 | 109 | 120 | 90-300 | ||

Physical Properties

| Property Class Diameter | 8.8 M 16 M16 |

10.9 all diameters |

||||||

| Unit | N/mm2 | kgt/mm2 | N/mm2 | kgt/mm2 | N/mm2 | kgt/mm2 | ||

| Tensile Strength, Min. | 800 | 81.5 | 830 | 84.6 | 1040 | 106 | ||

| Yield Strength, 0.2% offset Min. | 640 | 65.2 | 660 | 67.2 | 940 | 95.8 | ||

| Proof Lead Stress. | 580 | 59.1 | 600 | 61.2 | 830 | 84.6 | ||

| Shear Strength, Min. | 480 | 48.9 | 498 | 50.8 | 624 | 63.6 | ||

| Hardness | Brinell | HB | 219-285 | 242-319 | 295-362 | |||

| Rockwell | HRC | 20-30 | 23-34 | 31-39 | ||||

| Elongation % on GL = A = Cross Sectional Area |

12% Min. | 9% Min. | ||||||